How to Make Soldered Jewelry, Episode #3 - Stacking Rings

This is Episode #3 in our How to Make Soldered Jewelry video series. Create your very own unique and beautiful stacked rings! Instructor Aisha Formanski teaches you how to size, cut, shape and solder rings that will fit perfectly. The class takes the technique to the next level by adding texture and small blanks to the rings to add variety when stacked. >> Scroll down for the list of tools.

Here is a link to the Ring Sizing Guide.

hey there i'm Lisa Niven Kelly here for

Beaducation.com and in this video we're

gonna teach you how to solder a very

simple ring out of wire and then a

couple things you can do to embellish

out rings so you can make your own stack

of rings this class is actually taught

by I should hermanski and it's one that

we've had on our site for a bunch of

years but the content is perfect for the

soldering series that we've put together

so if you've stumbled on this class just

to learn how to make stock rings welcome

but if you're following our soldering

series this is episode three so the

first episode we talked about tools and

materials we don't do any soldering we

don't even light up a torch we just talk

about what you need in a second episode

we do line up a torch and we talk about

sweat soldering which is soldering two

flat pieces together and in that episode

we used sheets on ER we cut a little

piece off a little pal Ian or it's also

called a chip and soldered with that but

you could have also used paste solder or

wire solder if you're gonna use wire

solder I probably would have hammered it

flat so I had a flat piece in between

the two so in that class we use the

sheet solder but in this class i shows

how to solder the ring shut with wire

solder a really fun way to apply it and

she also shows with paste solder I'll

just turn it over to ice you know and

she's gonna teach you how to make some

stacked rings the first step to making a

ring is doing a little bit of math I

know for a lot of you this class

starting and seeing math was maybe not

your dream but I'm gonna walk you

through it it's super simple so let's

let's just dive right in here so I'm

going to make a size six ring today with

round wire that is 14 gauge so what I'm

going to do is I take the inner diameter

for a size six ring which is sixteen

point five one and I add the thickness

of the metal one point six three

millimeters which is the thickness of

our wire which equals eighteen point one

four and then you're going to multiply

the

by pi which gives us fifty six point

nine five which gives you the total

length that you're gonna cut your

material down to now this is a pretty

precise number so I'm just going to

round up and make that fifty seven you

can find a handy table that gives you

all the us ring inner diameter sizes and

all the details on this math under the

instruction section as you see I've

measured and marked at fifty seven

millimeters and I want to point out here

see how this little end is popping up

like that you really want to make sure

that this is exact so I'm just gonna

push that down to show that it's exact

ring sizing is very very precise half a

millimeter or a full millimeter will

bump you into a different ring size I'm

gonna bring in my heavy-duty flush

cutter here this is my favorite cutter

and we're using pretty thick wire here

today so I want to remind you to cut far

back in the jaws you don't want to cut

out in the tip here it's not the

strongest place on the cutter so let me

get this all lined up for you I want to

show you here that I'm placing the

cutter and even though the handle

appears to be coming out at an angle can

you see how nice and straight the wire

cut edge is to the line of wire this is

where you want to be

now we have this really nice razor flush

cut edge I want to bring in the file and

do a little cleaning up you can see here

you see that little line when the two

blades pass one another they leave this

just this little hair of a line I'm

going to remove it using a file now

sometimes when you file just up here in

the air unsupported it's really hard to

keep a flat and straight line so I'm

going to show you a couple tricks you

can use the handy dandy riveting steak

now you find the hole that fits your

wire

and poke it through now keeping in mind

what I just said about removing metal we

don't want to remove a lot of metal

right because then our ring will be too

small but you can support the wire let

me ankle this so you can see it you can

support the wire inside the ribbiting

stake and just have that little bit

sticking out so you can feel it and then

take your file and remove the excess

another tool you can use is the miter

jig I love my miter jig you're going to

see this in this class a couple of times

as you see I've placed the wire through

the jig and just have a little bit

sticking out here and then I'm going to

tighten down here nice and tight bring

in that file again and just remove the

very end

run my finger across it that feels

really good so we now have two perfectly

flat and flush ends here's one of my

favorite parts of this process is

shaping the ring and preparation for

soldering now you would think that we

would want to make this into a perfect

circle but we actually don't and it

actually doesn't even really matter that

much what shape it is at this part the

most important part is that the two ends

come together and meet nicely together

you've noticed while I've been talking

I'm already manipulating the wire and

I'm just starting to add a curvature

into the center and I'm using the medium

wrap and tap to pull the one end in

words like that flip it over and do the

same thing on the other end what I'd

like to really press at this step is

that this is not a fast part of the

process this is really just a lot of

tweaking and torquing and and getting

those two ends to meet so let's just

work on that here for a little bit

that ends looking pretty good get this

other side in

I must admit I may have put on too much

hand lotion here this is a little

slippery we're getting there and getting

warmer I'm not gonna bring in my chain

nose hair just start to move the two

ends together kind of like opening and

closing a jump ring all right here we go

we are getting close can you see that

little gap it's like a little bit of

work to do bring my we wrap and tap back

in here and I like to build tension by

Criss crossing the two ends passing them

past each other and then pulling it back

together you can probably hear the

clicking as they pass back and forth get

in there with your hands if you need to

filling that tension and working it back

and forth and that looks pretty good and

remember the success to a great solder

seam is to flat flush ends together with

no gaps to hold up my ring while I

solder you'll notice here I have this

notch carved into my kiln brick and it's

very easy to do with a tweezer and the

other little sharp point you just take

your tip and carve into the soft stone

you can do this on charcoal as well I'm

first going to show you how to solder

using solder paste here's my little

solder paste I'm using easy solder paste

are also known as soft this has the

lowest flow temperature and why not

because we're not going to be

introducing any other solder to this

piece so this is actually quite a bit I

would recommend putting on maybe the

equivalent of what would be it maybe a

size 11 seed

if you wanted to get really particular

maybe a size of 10 seed bead it's just a

little dollop I'm just gonna adjust this

a little bit

so I know you can't see me but I have my

hair pulled back my safety glasses on

because safety is always first right and

let me walk you through what we're gonna

do here I'm gonna ignite my butane torch

and then I'm gonna slowly heat the ring

I'm actually gonna have a flame pretty

far back this ring is pretty small so we

don't want to shock the metal so keeping

in mind just lately warming in a

circular motion then the binder is gonna

burn away so you're gonna see a little

bit of smoke and then we'll be a little

sneaky little flame which is my

indicator to move in closer with my heat

and focus on the scene the reason I'm

talking you through this now is that

it's gonna happen pretty fast so let's

turn down the lights in the studio so

you can see the action a little bit

better

[Music]

[Music]

there we go this is one of my favorite

parts the quenching I know this is not

real pretty right now we've got a fire

scale all over but I wanted to show you

that the seam is closed and next I want

to show you how to solder using Sutter

wire now I'm going to show you how to

solder the ring seam using wire solder

first I'm going to apply a little bit of

flux on the seam the top and the bottom

here not too much because the solder

will flow where the flux is so you don't

want to make a big ol mess now let's

talk through this a little bit because

it's gonna happen really fast so what

I'm going to do is I'm going to ignite

the torch and I'm gonna slowly in a

circular motion heat the ring heating it

consistently now just as it starts to

get warm I'm going to bring in the

solder wire and I'm going to touch it to

the seam so as the ring heats up and

gets to temperature to melt the solder

it'll flow now there's a happy medium

between oh it started to flow and then

pulling away and oh it started to flow

I'm just going to let it continue to

flow and go forever I'm going to turn

down the studio lights here so you can

see more closely

there we go that worked pretty well I'm

gonna go ahead and crunch it and then

we'll bring up the house lights so you

can get a nice look here is the Sutter

seam once again not so pretty but I'm

going to clean it up and we'll move on

to the next step

let's now shape the ring and slide this

on a steel ring mandrel here and pull it

down as far as I can and I'm gonna

lightly tap it with a plastic mallet

really briefly I want to touch base and

talk about the fact that this is now

really soft because we heated it with a

torch it's now annealed most likely

while shaping the ring into a true round

shape it's going to grow about a quarter

of a size this is something that you can

just take note of while you're making

your first rings and make adjustments in

your original measurement for the next

round I just continue to lightly tap

this is not a heavy-handed task

sometimes I like to take it off and flip

it around just to make sure it's

consistent let's take it off and check

it here oh what's there

this is looking pretty good I want to

show you a little something here from

the side it's a little wavy it's not on

a flat plane so I'm going to bring in

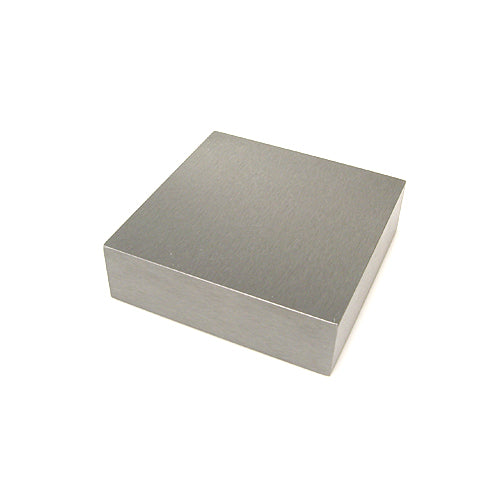

the bench block and we're gonna give it

a couple couple whacks I've placed the

ring on a bench block and this is a good

example of what happens to a well used

or well-loved bench box see all those

little dings and nicks I don't want

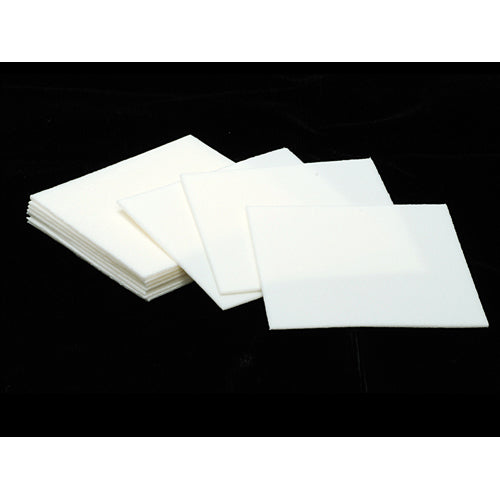

those to transfer to my metal so what I

do is I take a pro polish pad and I just

lay it down on the bench block this puts

a little buffer between the soft metal

and the bench block and then I'm gonna

give it a couple whacks flip it around

[Music]

pretty much all it takes let's put it on

the ring mandrel and see what size that

it was remember what I said about the

stretching so remember we are making a

size six so let's see how this played

out six and a quarter so the ring

stretched a quarter of a size so next

time I made a ring if I needed to be a

really specific size I would make an

adjustment in my math here is the

finished ring I think it looks pretty

good turned out pretty great here's the

little seam you can kind of see it now

if you had excess solder say a mound

here on the outside or on the inside you

could use a fine grit sandpaper such as

400 grit or even finer to just rub away

the excess you also could use silicon

discs with a rotary tool or for them

that works super good this is pretty

great let's take a look at some other

things that you can do these are some

some rings I made in preparation for

this class I'm super excited how they

turned out the first one on the far left

I use a chasing hammer to create that

nice kind of traditional hills and

valley texture

the center one I used our slash stamp to

just create some nice defined lines the

third one of course is just plain and

simple I like them tailor this way

remember when you add texture or design

stamps to your ring you're going to want

to use a sandbag and a ring mandrel

let's read your ring onto your ring

mandrel nice and tight place it on your

sandbag the stabilizes it and you'll be

good to go to work away and rotate also

remember anytime you add design or

texture you're dispersing the metal not

removing it which means the ring is

going to grow a little bit more and you

might ask well how much more is it gonna

grow and it's really gonna depend on how

much stamping and how much texturing you

at the ring here are a bunch of rings

these are just simple plain round wire

rings like we did in the first section

of class these are the textured and

stamped round wire rings I think turned

out great

now these two you haven't seen yet these

are using our thin rings which are

already made for you and then adding

texture using the nine face texturing

hammer and then this one just has little

stars with a little period stamp between

each star then there are the rings that

we've added the solder ball tool of

solder balls - these ones are the solder

balls and they worked great I wanted to

talk a little bit about this one this is

our small classic heart it's not a

solder ball it has a little it's a

little bit larger so I actually had to

create a little cur

in the heart so that it had

surface-to-surface touch with the ring I

did that by squeezing it with the ring

bending plier also remember sterling

silver charms are a great addition to

stacked rings you can just trim off the

loop and solder them straight on one

last thing stamping is a great little of

detail to add to the front of these

little these little solder balls and

blanks you could do an initial or design

and be really cute

[Music]